|

Welcome To Evlithium Best Store For Lithium Iron Phosphate (LiFePO4) Battery |

|

In June 2024, Sungrow undertook a groundbreaking initiative by conducting a controlled combustion of its 10MWh PowerTitan 1.0 liquid-cooled battery energy storage system (BESS). This test marked the first large-scale burn assessment of an energy storage system worldwide. Building on this achievement, the company recently invested approximately 4.23 million USD in executing the world’s largest burn test on its 20MWh PowerTitan 2.0 liquid-cooled BESS, showcasing its focus on safety innovation.

These tests, carried out within six months, underscore Sungrow’s dedication to advancing product quality and ensuring safety at energy storage facilities. They also reflect the company's efforts to set higher safety standards for the entire energy storage industry.

The 20MWh burn test, designed to replicate real-world fire conditions in a power plant, was supervised by experts from DNV (Det Norske Veritas) and observed by over 100 clients. The outcomes exceeded expectations, with no fire propagation during a simulated thermal runaway event. Unlike conventional industry tests, Sungrow's approach emphasized extended burn durations, stringent testing conditions, and elevated safety benchmarks.

The burn test subjected the PowerTitan 2.0 to over 25 hours of continuous combustion, significantly longer than the typical 4-8 hour industry standard. Despite the extended exposure, the container structure remained intact, and the system was safely removable. The fire was confined to the affected unit, illustrating the product's superior explosion venting, flame retardancy, and impact resistance.

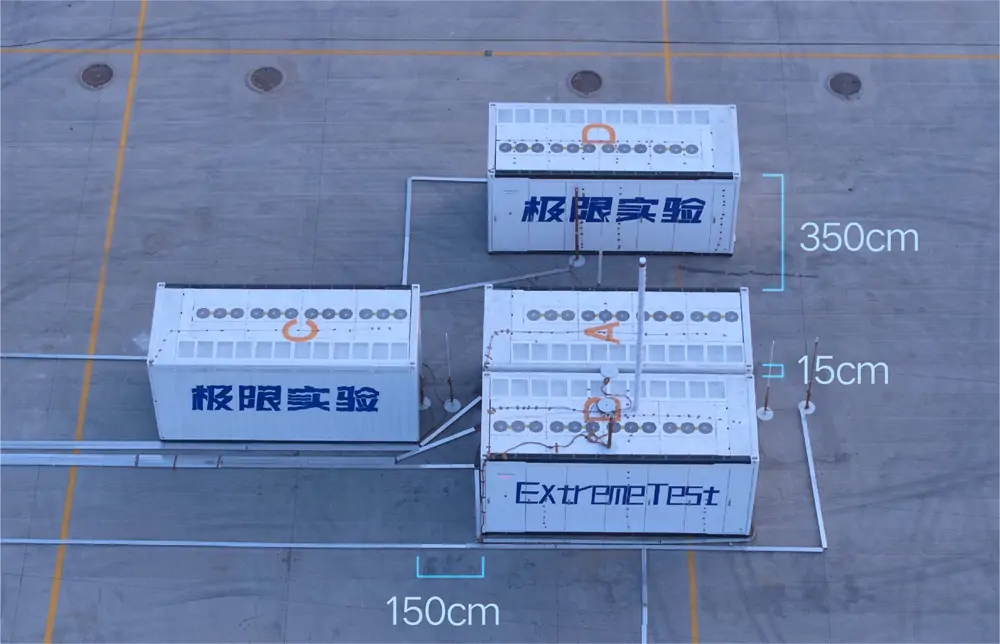

The test simulated harsh operating scenarios, positioning containers only 15 cm apart—far closer than the standard 3 meters. Flames from the burning container reached 1,385°C, a temperature capable of melting steel, yet neighboring containers maintained a safe temperature of 40°C, confirming the PowerTitan 2.0's advanced thermal insulation.

To test its autonomous safety design, all active firefighting systems were disabled during the burn. Despite this, the container doors remained intact, and the fire was confined within the unit. This outcome demonstrated the robust passive fire protection system, designed to mitigate risks without external intervention.

Safety remains a critical priority in the energy storage sector. Sungrow’s high-stakes testing of the PowerTitan series not only validates its products' safety features but also establishes a new industry benchmark. These rigorous assessments provide valuable data to guide the development of future safety protocols, reinforcing Sungrow’s role as a leader in advancing energy storage system safety standards.

Edit by paco