|

Welcome To Evlithium Best Store For Lithium Iron Phosphate (LiFePO4) Battery |

|

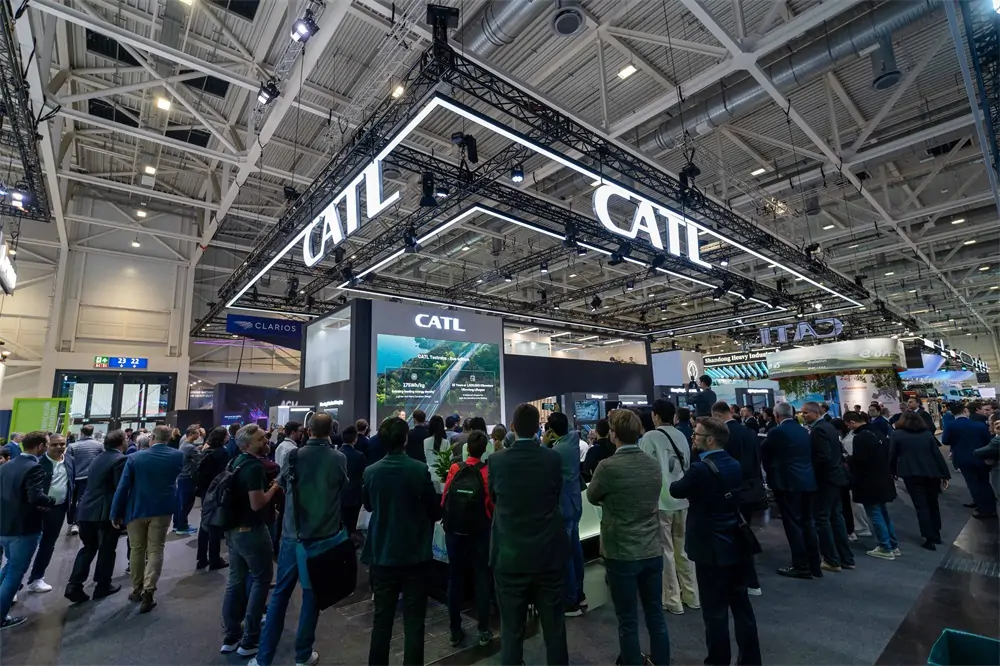

At IAA Transportation 2024, Contemporary Amperex Technology Co., Limited (CATL), a global leader in new energy technology, introduced its revolutionary TECTRANS battery system, set to redefine the commercial transportation sector.

The TECTRANS system marks a major breakthrough in commercial vehicle battery technology, delivering unmatched energy density, faster charging speeds, and enhanced durability. This cutting-edge solution is designed to reshape the electric commercial vehicle landscape, offering fleet operators extended range, reduced downtime, optimized cost efficiency, and improved overall performance.

For heavy-duty trucks, CATL has launched two innovative products: the TECTRANS - T Superfast Charging Edition and the TECTRANS - T Long Life Edition. The Superfast Charging Edition features a remarkable 4C peak charging rate, enabling a 70% charge in just 15 minutes. This rapid charging capability significantly reduces vehicle downtime and boosts operational efficiency.

The TECTRANS - T Long Life Edition sets a new industry standard, offering an extraordinary lifespan of up to 15 years or 2.8 million kilometers. This durability is crucial for demanding commercial operations, particularly in high-frequency, energy-intensive environments such as port operations and bulk transportation. Both editions provide an impressive driving range of up to 500 kilometers, meeting diverse operational needs from short-haul deliveries to long-distance transport.

The TECTRANS - Bus Edition is a state-of-the-art solution for long-distance passenger transport, boasting an industry-leading energy density of 175Wh/kg—the highest for LFP chemistry in bus applications. Its compact design supports long-range capability and low energy consumption, enhancing vehicle layout flexibility. The advanced thermal management system optimizes performance across various climates, reducing internal temperature disparities by 50% and ensuring long-term reliability even in extreme conditions.

In July, CATL introduced its light truck solutions in China, broadening the TECTRANS lineup to cover a wider range of commercial vehicle applications. These solutions, with enhanced energy density and fast-charging capabilities, address the unique demands of urban delivery and last-mile logistics.

Akin Li, Executive President of CATL Overseas Business, emphasized the proven reliability of CATL batteries in diverse environments: "Our batteries have demonstrated exceptional performance in extreme conditions, from enduring temperatures above 45°C in Qatar and Dubai to operating in -35°C climates in Norway and Sweden. The TECTRANS system and its product lines underscore our dedication to advancing energy transition through continuous innovation."

The commercial vehicle sector faces significant challenges in its transition to electrification, including charging times, costs, and range limitations. The TECTRANS system aims to address these issues by integrating several advanced technologies, resulting in superior performance in energy density, charging speed, and cycle life.

"As a global industry leader, CATL is committed to pushing the boundaries of what's possible in electric transportation," said Akin Li. "TECTRANS represents the culmination of our extensive R&D efforts and is a significant step forward in commercial vehicle electrification. We are excited to showcase this technology at IAA Transportation and demonstrate how it will accelerate the global shift towards sustainable transport."

At this year’s IAA Transportation, CATL is showcasing a broad range of battery solutions tailored for different applications, including trucks, buses, ships, and construction machinery.

Beyond delivering safe, reliable, and cost-effective products and services to support global climate goals, CATL is committed to sustainable practices throughout the battery lifecycle. The company aims to achieve net-zero emissions in battery manufacturing operations by 2025 and across the entire battery supply chain by 2035. These milestones will reduce emissions by more than 40% over the lifespan of an electric vehicle. CATL has already achieved carbon neutrality in nine of its factories.

The company has established seven major recycling hubs globally. Its subsidiary, Brunp Recycling, achieves recovery rates of over 99.6% for nickel, cobalt, and manganese, and 91% for lithium. With the capacity to process 270,000 tons of used batteries annually, CATL is leading the way towards producing batteries entirely from recycled materials, significantly reducing the need for new mining operations.

Edit by paco

All Rights reserved © 2025 Evlithium Limited